Filtration & Separation

Contamination is a major cause of costly downtime and maintenance across all industries, including Oil & Gas, Chemicals & Fertilizers, Power Generation, and Water Treatment.

Fluid Technology offers end-to-end filtration solutions tailored to critical sectors, leveraging Pall Corporation’s expertise in filtration, separation, and purification. We work closely with customers to tackle their toughest challenges, ensuring safety, preserving vital assets, enhancing product quality, and reducing emissions and waste.

Products

Particulate filters for Liquid and Gas

Pall’s gas and liquid particulate filtration systems are specifically designed to eliminate primary contaminants that contribute to system inefficiencies and failures. The filter elements are available in both depth and pleated media configurations, offering enhanced surface area and extended service life. The product portfolio includes Ultipleat® High Flow, Ultipor®, Profile® Coreless, Nexis®, and Claris® filters.”

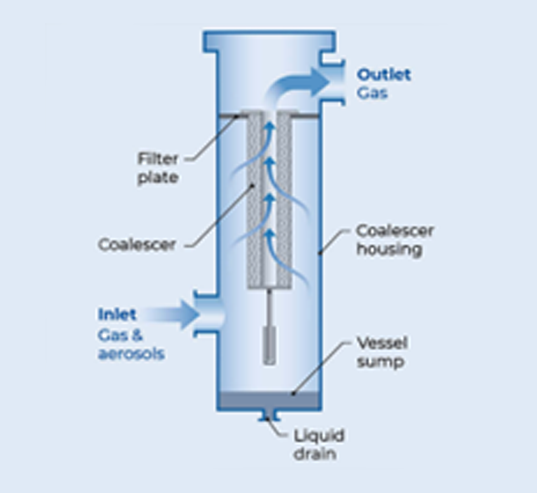

Liquid/Gas Coalescers

Pall’s liquid/gas coalescers are engineered to efficiently remove entrained liquid aerosols—such as condensed hydrocarbons and pipeline treatment chemicals—from gas streams. Utilizing a graded media matrix, these coalescers facilitate the merging of fine liquid droplets into larger ones, enabling more effective separation. Each coalescer is chemically treated to reduce the surface energy of the filtration medium, thereby enhancing the rapid drainage of collected liquids. Pall’s offerings in this category include SepraSol and SepraSol® Plus liquid/gas coalescers.

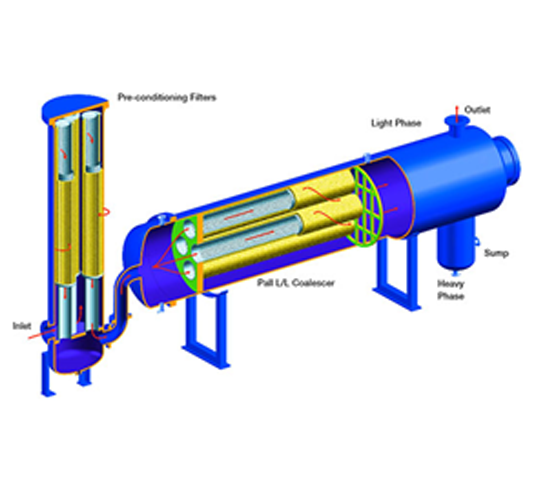

Liquid/Liquid Coalescers

Pall liquid/liquid coalescers are specifically engineered to facilitate the efficient separation of liquid emulsions. Constructed from a range of advanced polymers and fluoropolymers, these high-performance coalescers maintain effectiveness even in applications characterized by low interfacial tension and the presence of surfactants, without compromising operational integrity. Their extended service life minimizes the frequency of cartridge replacements, thereby reducing maintenance requirements and waste disposal costs. Pall’s product line includes AquaSep® Plus, PhaseSep® EL, and Medallion™ liquid/liquid coalescers.

Hydraulic and Lubrication Filtration

The Pall Athalon™ series integrates cutting-edge media design with stress-resistant technology to deliver exceptional filtration performance and long-term value. Engineered for demanding industrial applications, Athalon filters offer the following key features:

Consistent High-Efficiency Filtration

Delivers sustained performance throughout the filter’s service life, with a Beta X(C) rating exceeding 2000.

Optimized Pleat Configuration

Innovative laid-over pleating maximizes filtration surface area, enhances flow capacity, and enables compact element design.

Stress-Resistant Media Technology

Provides superior durability under challenging operating conditions, ensuring reliable performance.

Electrostatic Discharge Control

Anti-static construction minimizes electrostatic charge generation during high-flow operations, enhancing safety and system integrity.

Fluid Condition Monitoring

Pall offers an extensive selection of advanced fluid condition monitoring systems, engineered to support industrial manufacturers and equipment operators in precisely evaluating essential performance metrics. These include fluid cleanliness levels, moisture content, and differential pressure ensuring optimal system reliability and operational efficiency.

Expert Technical Services

Contamination Mapping & monitoring

Pall’s Scientific and Laboratory Services (SLS) team delivers tailored solutions for customers facing complex filtration, separation, and purification challenges—particularly those with limited time, resources, or equipment. Leveraging deep expertise in production processes and performance optimization, SLS scientists offer both on-site and off-site support, including laboratory analysis and pilot-scale testing.

With state-of-the-art laboratories strategically located across the globe, Pall’s SLS provides advanced capabilities in testing, failure analysis, and process validation—ensuring reliable, data-driven recommendations that enhance operational efficiency and product quality.

Rental equipment for fluid depollution

Pall Corporation offers a comprehensive range of rental equipment designed to support fluid depollution and purification needs across various industrial applications. These solutions are ideal for short-term requirements such as process upsets, pilot testing, or interim use while permanent systems are being installed. All rental options are designed for rapid deployment, require no capital expenditure (CAPEX), and deliver reliable performance.

- High-Flow Particulate Filtration Skids: Engineered to manage flow rates up to 2,158 m³/h (325,760 bbl/day), these skids ensure efficient removal of particulate contaminants from process fluids.

- Mobile Fuel Filtration Skids: Equipped with absolute-rated, high-flow filter cartridges, these systems maintain fuel cleanliness by effectively removing impurities from diverse sources.

- Modular Design: Many Pall rental skids feature a modular configuration, allowing flexible system integration tailored to specific operational requirements.

- Varnish Removal Systems: Designed to eliminate varnish and other degradation byproducts that compromise hydraulic and lubrication system performance.

- Diagnostic and Monitoring Equipment: Pall also provides rental access to advanced fluid analysis tools, including the PCM200 and PCM400 series fluid cleanliness monitors, enabling real-time condition monitoring and diagnostics.

Filter maintenance and equipment upgrades

- Pall Corporation delivers a full suite of maintenance and upgrade services designed to enhance the performance and extend the lifespan of filtration systems. These offerings include maintenance, repair, and overhaul (MRO) support for a wide range of Pall products. Notable solutions include Supralon™ filter element upgrades for hydraulic and lubrication applications, which improve system reliability and efficiency.

- Additionally, Pall provides retrofit options, engineered to elevate fluid cleanliness standards and reduce overall operating costs ensuring continued system optimization and long-term value.

Metallic elements cleaning

Over time, metallic elements within filtration systems may experience clogging or corrosion, leading to reduced operational efficiency. Pall’s specialized metallic element cleaning services are designed to restore these components to their original performance standards. By revitalizing filtration efficiency and extending service life, our cleaning solutions help maintain optimal system reliability and reduce replacement costs.

Rotating machine services

Rotating machine services, i.e., Lube Oil depollution, Cleanliness assessment and monitoring.

Key Applications

|

|

sales@fluid-tech.org

sales@fluid-tech.org

Oil & Gas

Oil & Gas Chemical & Fertilizers

Chemical & Fertilizers Aviation

Aviation Water & Waste Water

Water & Waste Water Food & Beverage

Food & Beverage Power

Power Mining & Minerals

Mining & Minerals

Filtration & Separation Solutions

Filtration & Separation Solutions Heat Transfer & Fluid Handling

Heat Transfer & Fluid Handling Water Quality Monitoring

Water Quality Monitoring Aviation Fueling Solutions

Aviation Fueling Solutions Flow Control Solutions

Flow Control Solutions Mining solutions

Mining solutions Rental Services

Rental Services Field Services

Field Services